With the rapid development of the fuel cell vehicle industry and the improvement of environmental protection awareness, the demand for fuel cell vehicles is increasing gradually, which has trigged the attention of hydrogen production and refueling infrastructure. By the end of 2020, a total of 553 hydrogen stations were in operation worldwide with 107 new stations added throughout the year.

A hydrogen refueling station is an essential infrastructure for fuel cell vehicles, however, it has problems such as occupying large space and high construction costs. Meanwhile, the current uncompleted laws, regulations, and permitting procedures make it impossible to popularize on a large-scale basis.

Therefore, renewable energy enterprises worldwide are trying to improve hydrogen station design, hoping to promote its distribution of it by reducing the footprint and investment costs, expecting it can be deployed in the city as easily as an EV charging station, Angstrom said in a statement.

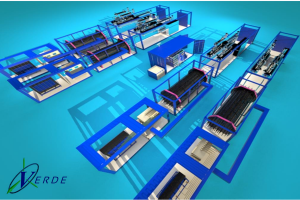

The emergence of the all-in-one hydrogen refueler solved the dilemma, it occupies a much smaller footprint and can produce hydrogen by connecting water and electricity only, which requires less investment cost. The refueler is more suitable for customer who has urgent refueling demand or relatively small hydrogen demand.

It can be used to promote the hydrogen market in the early state and let more people understand and use hydrogen energy. With the expansion of the entire hydrogen industry, the cost of refuel will progressively decrease and eventually become the major hydrogen production and refueling infrastructure for each household in the future.

“The Angstrom Group successfully developed the world’s first all-in-one hydrogen refueler in 2018. It is highly integrated and can be customized according to special requirements. The biggest advantage of the refueler is user-friendly and easy operation and maintenance.

“The raw materials for hydrogen production are only water and electricity, with intelligentized control and monitor ensure safety and reliability. Compared with traditional hydrogen stations, it reduces construction investment and labor costs,” the statement said.

Angstrom’s all-in-one hydrogen refueler has passed the professional test of Savannah National Laboratory in the US, which proves the advancement of the equipment.

The successful development of an all-in-one hydrogen refueler is a technological breakthrough based on the long development experience of the hydrogen industry and the mature knowledge of hydrogen station construction. It is a milestone in the industry and will help better promote the popularization of fuel cell vehicles, improve the utilization of hydrogen energy rate, and easily realize global carbon neutrality.

![[Latest] Global Data Center CPU Market Size/Share Worth USD 48.9 Billion by 2033 at a 15.2% CAGR: Custom Market Insights (Analysis, Outlook, Leaders, Report, Trends, Forecast, Segmentation, Growth, Growth Rate, Value)](https://energy.asia/wp-content/uploads/2024/12/global-data-center-cpu-market-2024-2033-by-billion--120x86.png)